THE ART OF WEAVING, SPINNING AND TAPESTRIES

(c) Tabitha Gilmore-Barnes Studio

WEAVING

SPINNING

TAPESTRIES

2026 UPDATE

This website will be closed around mid-Summer, as I focus more on the creative processes of weaving tapestries. A big thank you to Lisa Tait, Silvertop Graphics, and Brian Sweeney, Locust Grove Enterprises, for designing this site.

Watch for my monthly posts on Facebook and Instagram accounts for Tabitha Gilmore-Barnes Studio at: https://www.facebook.com/handwoventextiles and http://@tgbweavingstudio

Studio visits and inquiries are always welcomed, and email me at: tgbweavingstudio@hotmail.com. The Subject Line MUST read Studio Visit and Inquiry otherwise your email ends up being deleted as spam.

Photo below: my two tapestries at Longyear Gallery, Holiday Show: Artists Choose Artists 2025.

NEWEST TAPESTRY

HOSANNAH (c) 2026 was started mid-Summer 2025, and finished just recently. It is still on its stretcher frame loom, waiting to be washed, hemmed, and framed.

The word HOSANNAH comes from Psalm 118 which is used in the Feast of the Tabernacles = Succoth/Pentecost, which occurs 50 days after Passover/Easter. It was also used by the public as they welcomed Jesus into Jerusalem on Palm Sunday, at the beginning of Passion Week. It means “save us, we pray”. The 7 branched Temple Menorah is juxtaposed with the Tree of Life (Genesis 2 and Psalm 1).

VIDEO PROFILE

In this video, curated by Jan Albert and filmed by Kent Garret, Tabitha discusses what excites her about being a weaver, and how she is moving from creating textiles on her AVL Loom to ‘drawing with wool’ to create tapestries. She joined the Catskilled Crafters in a “Get to Know Your Neighbors” Zoom event hosted by the Pine Hill Community Center on February 25, 2021. An excerpt of this video is available for viewing. Click here.

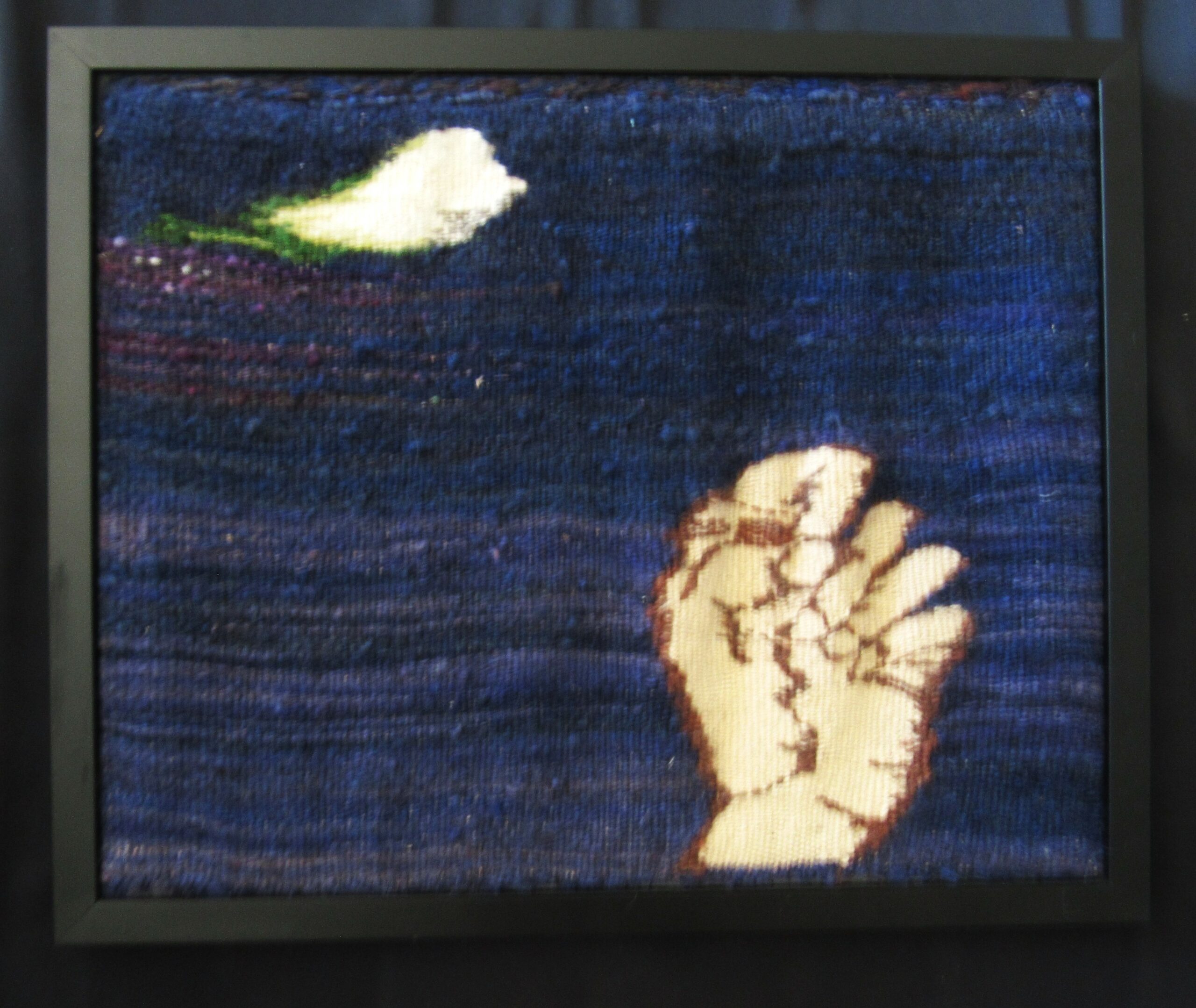

“THE THINGS I NEVER SAID” 2026

My tapestry Lily Pond (c) 2025 has been juried into the upcoming Exhibit at the Roxbury Arts Group, “The Things I Never Said”. This tapestry was woven specifically and juried into last year’s “SANCTUARY” Exhibit at the Woodstock Artists Association and Museum — https://tabithagilmore-barnesstudio.com/portfolio/lily-pond-c-2025/.

“BRING HOME THE COLORS OF THE CATSKILLS™”

UPDATED March 2022: COPYRIGHT NOTICE These images are Copyrighted by Tabitha Gilmore-Barnes Studio. All reproduction rights reserved. All images included in this website are protected under international copyright law. Any reproduction or other use of the images without the express written authorization of the artist is strictly prohibited. Copyright does not transfer to buyer upon sale, the Copyright remains with the Artist. The Copyright Act gives the Copyright owner, in this case, the Artist, the exclusive right to reproduce or modify their work. This means you may not download, scan, print, copy or crop/edit any of the images even if you have paid for and physically own the artwork. Copyright remains with the Artist for his or her lifetime plus 50 years before entering the public domain. To learn more about copyright law, click here: https://whatiscopyright.org/